Thursday September 4, 2025

Boeing and WestJet have announced that the Canadian airline will purchase 67 additional Boeing aircraft—comprising 60 737-10 jets with, options for 25 more, along with seven 787-9 jets,with options for four more—bringing its confirmed order to 123 as it ex...

Read More »Thursday September 4, 2025

Jordan Airmotive (JALCo) has announced the further expansion of its cooperation with Aeolus Engine Services, a provider of aviation leasing and asset management. Under this agreement, the first CFM56-7B engine from the programme has been fully overhauled and d...

Read More »Thursday September 4, 2025

MTU Maintenance has appointed Frank Haberkamp as Managing Director of MTU Maintenance Serbia, effective from September 1 2025. He succeeds Rainer Becker, who has been with the facility since the project phase and, following a handover period, will return to th...

Read More »Thursday September 4, 2025

Etihad Airways has reported its best-ever half-year performance, achieving record profits and passenger numbers in the first six months of 2025. The results highlight sustained momentum in network growth, operational efficiency, and an enhanced customer experi...

Read More »Thursday September 4, 2025

Lufthansa Technik expanded its Cyclean Engine Wash solution across Europe through a new partnership with ACC Columbia Jet Service. As of August, ACC Columbia Jet Service started providing on-site engine core wash services for commercial aircraft as an authoriz...

Read More »Thursday September 4, 2025

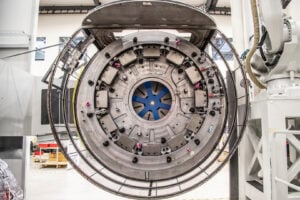

GKN Aerospace has announced the expansion of its Newington, Connecticut facility with a new production line dedicated to additive manufacturing of the fan case mount ring (FCMR), a vital component of the Pratt & Whitney GTF engine that powers the Airbus A2...

Read More »Wednesday September 3, 2025

Amedeo has disclosed the successful closing of the sale of two Airbus A380-861 aircraft to Emirates. These transactions mark the first stage of a broader four-aircraft agreement, with the remaining closings scheduled to take place in the fourth quarter of 2025...

Read More »Wednesday September 3, 2025

TAT Technologies, a provider of aerospace thermal management and MRO solutions, has announced the establishment of FutureWorks, its Centre for Aerospace Innovation, based in Charlotte, North Carolina. FutureWorks represents a bold step forward in TAT’s missi...

Read More »Wednesday September 3, 2025

Sumitomo Corporation, SMBC Aviation Capital, Apollo, and Brookfield have announced their definitive agreement to acquire Air Lease Corporation (Air Lease), a aircraft lessor founded by Steven F. Udvar-Házy and John L. Plueger, with a portfolio primarily compr...

Read More »Wednesday September 3, 2025

Titan Aviation Leasing, a subsidiary of Atlas Air Worldwide, and Bain Capital, have announced the closing of Titan Aircraft Investments II (TAI 2), a new freighter aircraft investment platform. TAI 2 launches with a capital commitment of US$410 million from Ba...

Read More »Wednesday September 3, 2025

Azorra has delivered the first new Embraer E190-E2 twin-engine passenger aircraft to Virgin Australia, marking a new airline partnership for the lessor and the introduction of the type with a major airline group in Australia. Virgin Australia Regional Airlines...

Read More »Wednesday September 3, 2025

Collins Aerospace is expanding its facility in Tajęcina, Poland, to increase production of landing gear systems for key commercial and defence aircraft. The 4,000 m² expansion will strengthen RTX’s operational capabilities in Poland. The company currently ...

Read More »Wednesday September 3, 2025

Aircraft Leasing & Management (ALM), has confirmed the purchase by Fuyo of two Boeing 737 MAX 8 aircraft from BOC Aviation (BOCA). The aircraft, bearing registration numbers PH-TFT (MSN 44610) and PH-TFU (MSN 44652), are currently on lease to TUI Airlines....

Read More »Tuesday September 2, 2025

Macquarie AirFinance has acquired 30 Boeing 737-8 aircraft, marking the company’s second direct order with Boeing. This strategic expansion reflects growing airline demand for fuel-efficient aircraft, driven by rising passenger traffic and a stronger focus o...

Read More »Tuesday September 2, 2025

BCT Aviation Maintenance has announced two new line maintenance contracts at East Midlands Airport (EMA), after significant growth in cargo operations at its home base. Having recently begun freighter flights on behalf of Chinese logistics firm YunExpress, ope...

Read More »Tuesday September 2, 2025

National Jet Express (NJE) has announced the acquisition of two additional De Havilland Dash 8 Q400 turboprop aircraft. This development, which was foreshadowed earlier in the year, reinforces NJE’s commitment to expanding its operational capacity and streng...

Read More »Tuesday September 2, 2025

Deucalion Aviation has confirmed the long-term lease extension of two Boeing 737-800 aircraft with Norwegian Airlines, effective from August 21st 2025. The extension strengthens an already well-established relationship between the global aviation asset manager...

Read More »Tuesday September 2, 2025

SalamAir has announced the arrival of its 15th aircraft, a new Airbus A321neo, named “Barr Al Hikman” after the renowned coastal area in the Sultanate of Oman, often called the “Maldives of the Middle East” for its natural beauty and rich wildl...

Read More »Tuesday September 2, 2025

HAECO has signed a new base maintenance agreement with Brussels Airlines. Beginning in September 2025, HAECO will support the airline’s Airbus A330 fleet at its 22-bay hangar facilities at Hong Kong International Airport (HKIA). The agreement will run for th...

Read More »Monday September 1, 2025

Landing Gear Technologies (LGT), has announced the sale of a majority stake in the company to Setna iO, an established aircraft parts supplier headquartered in Chicago. The strategic transaction is intended to accelerate LGT’s growth whilst safeguarding its ...

Read More »