Veryon, a provider of information services and software solutions for the aviation industry, has introduced Veryon AIRE. This AI-powered data intelligence platform is designed to redefine how operators maximise aircraft availability, airworthiness, and reliability.

Veryon AIRE combines the industry’s largest de-identified dataset with proven data science and decades of real-world aviation expertise. It powers conversational, predictive, and decision-support capabilities that help operators turn unscheduled events into more scheduled and expected outcomes. Maintenance teams gain efficiency, foresight, and confidence in every decision.

With Veryon AIRE, operators can expect:

Smarter, faster fixes: The system recommends the most likely corrective actions to increase first-time fix rates. It also allows technicians to ask publication-specific questions and go straight to troubleshooting steps.

Intelligent fleet management: The platform automates routine tasks, lowers maintenance costs, and optimises critical maintenance planning and inventory control.

Enhanced reliability: Veryon AIRE identifies chronic issues, rogue components, and short-life parts. It also tracks degradation trends early, preventing unexpected aircraft-on-ground events.

How AIRE powers the Veryon portfolio:

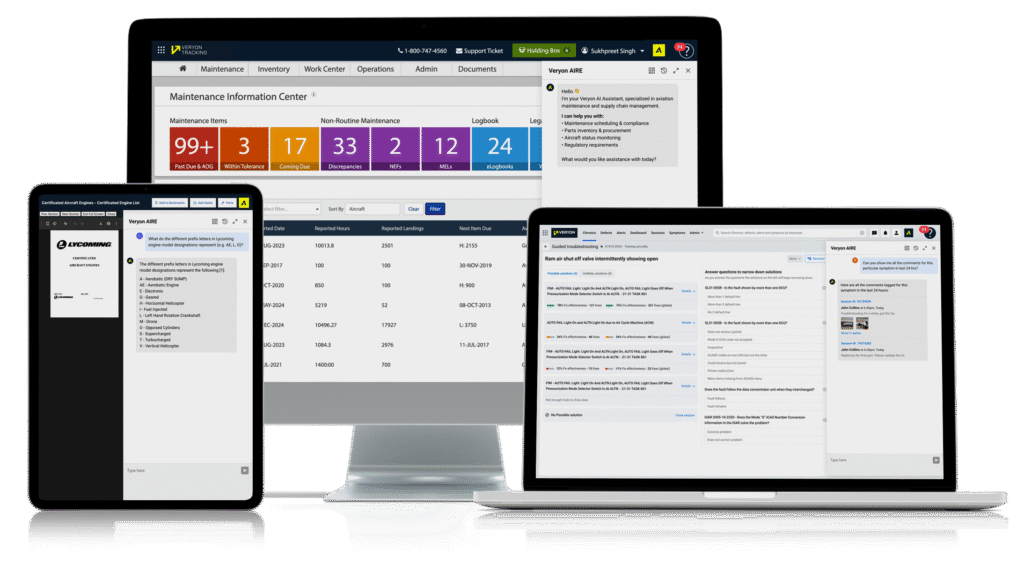

Veryon AIRE brings generative AI to life across the product suite in three ways — conversational intelligence, predictive analytics, and decision support. Together, these features strengthen efficiency and provide valuable insights for operators.

Veryon Diagnostics: AIRE acts as an analytics engine that mines logbook data and manuals. It delivers insights such as operator versus global fix rates, quick troubleshooting references, and detailed defect histories tied to the initial symptom.

Veryon Tracking: AIRE serves as a conversational AI interface for maintenance and inventory data. Operators can check aircraft status, manage parts, plan for maintenance, and maintain continuous compliance.

Veryon Publications: AIRE enhances technical publications with a conversational AI interface. Engineers can ask questions about work instructions or tasks and identify the exact parts required, making complex information instantly actionable.