Within the framework of the new production area at the S7 Technics base in Mineralnye Vody, floor panels and interior panels for the Airbus aircraft cabins will be produced. With an additional production area of 42 m², it will be possible to produce from ten to 20 products per working shift.

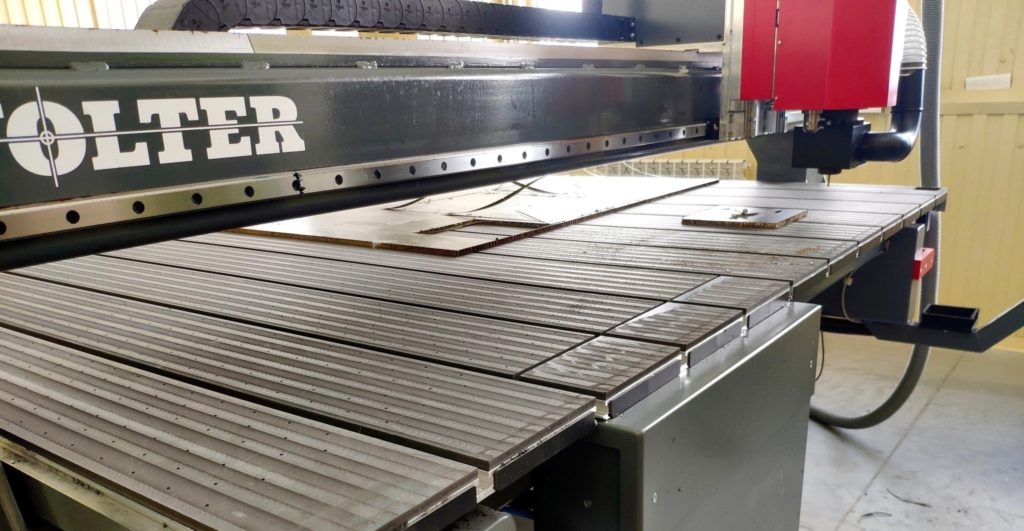

Aircraft panels will be manufactured from composite materials approved by aircraft manufacturers by milling on a high-precision computer numerical control (CNC) machine made by the Czech company Volter. The complex work, starting with graphic processing (creating a 3D model of panels, preparing programs for CNC machines) and ending with certificate release for a finished product, will be performed by experienced S7 Technics specialists who have already completed the training in working with CNC equipment and programming.

The pre-requisites for the creation of such a production area were plans to automate part of the work of the S7 Technics’ structural repairs department.

Previously, the panels were made by hand tools by the specialists of the aircraft structural repair shop. With the addition of the production area, S7 Technics has reduced the financial and time costs for panel production. For comparison, the purchase of ready-made panels from OEM companies is 20-30% more expensive, and it also takes a significant time for its delivery.