TARMAC Aerosave, an expert group in aircraft and engine lifecycle management and Donecle, a manufacturer of drones specifically for aviation maintenance purposes, have signed an agreement for drone aircraft inspections.

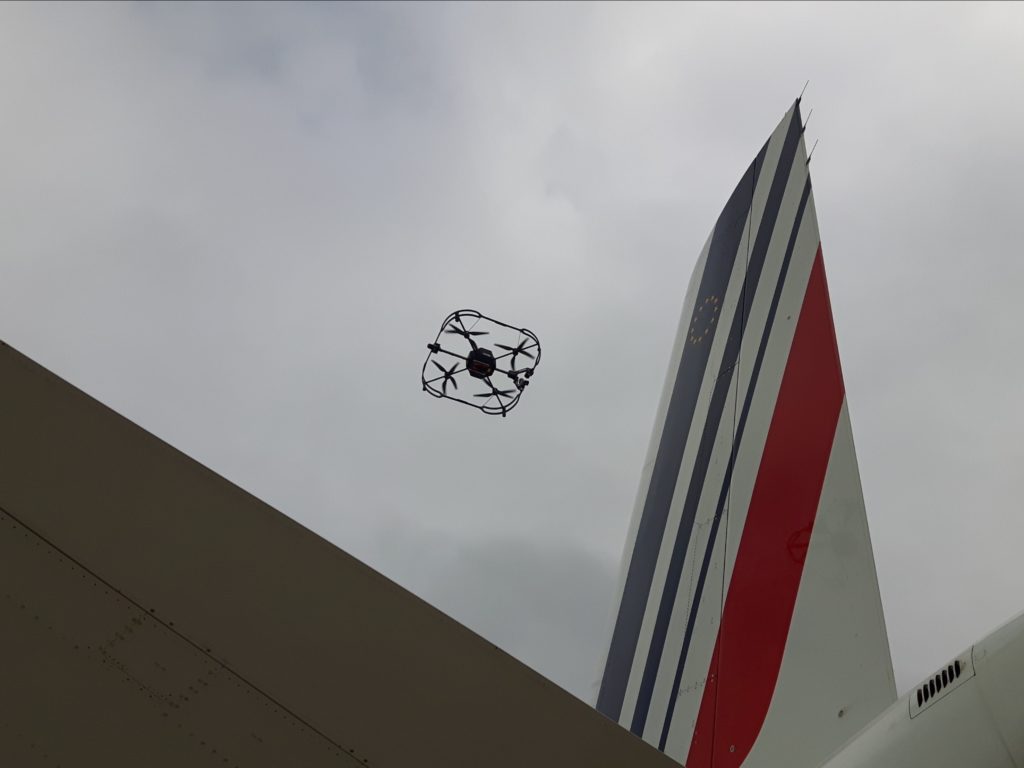

Donecle, based in Toulouse, France, is developing a range of automated solutions to optimise visual aircraft inspections. The Donecle system consists of a fully automatic flight – without a pilot or GPS – coupled to image analysis software and a secure platform for digital inspection monitoring.

As part of its innovating and permanent client satisfaction strategy, TARMAC Aerosave considered the Donecle drone solution with great interest.

Without being a substitute for maintenance procedures or mechanics, drones make it possible to carry out inspections in less than two hours – such as general visual inspections (GVI), lightning strike inspections, paintwork and regulatory marking inspections – thus making faster aircraft delivery to clients possible – whether on exit from storage or from maintenance. It is a valuable decision aid tool.

A successful test campaign was conducted by the two partners on the TARMAC Aerosave site in Toulouse-Francazal. The drone solution is currently fully operational for narrow-body aircraft in hangars. Developments are now focusing on the capacity to carry out inspections outside and on wide-body aircraft. The large number of aircraft accommodated by TARMAC Aerosave, the varied types, the regular flow of arrivals and departures and the three Tarbes, Teruel and Toulouse sites, allow Donecle to develop its products for every environment.

TARMAC Aerosave provides the largest aircraft and engine storage capacity in Europe, supported by maintenance, transition and recycling expertise. Its three sites in Tarbes (France), in Teruel (Spain) and Toulouse-Francazal (Francecan), together accommodate over 280 aircraft, while the maintenance activity covers the main commercial platforms (Airbus, Boeing, ATR). A dedicated engine workshop also handles the storage, transition, dismantling and repairs of CFM56 and LEAP engines. Using an environmentally-friendly approach, TARMAC Aerosave continues to develop advanced dismantling and recycling techniques that are recognised by ISO 14001 certification. It has a recovery rate of over 90%. TARMAC Aerosave also has ISO 9001, EN 9110 and EN 9120 certifications and is an EASA/FAA Part 145 and EASA Part