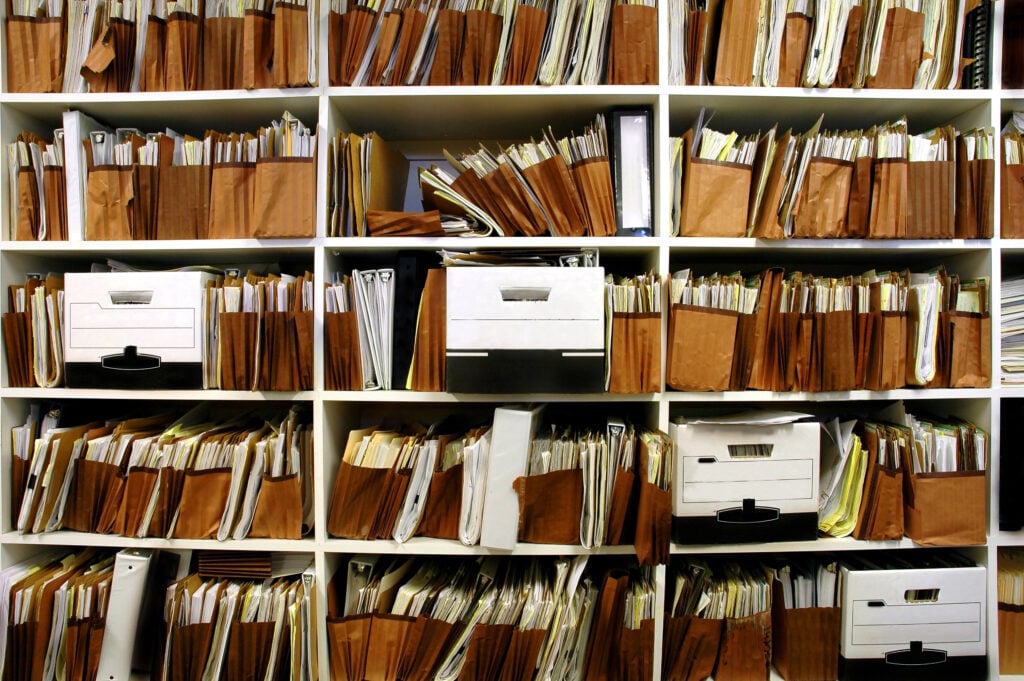

There is no question that digitisation of aircraft records helps in both increasing efficiency as well as reducing the massive volumes of paperwork traditionally involved in aircraft maintenance. However, the transition to digital records was never going to be a simple one, especially when one considers that impeccable and faultless record keeping is essential not only from a safety aspect, but also from the point of view of asset value. Incomplete maintenance records can substantially reduce the value of any aircraft, commercial or otherwise. We wanted to delve deeper into the world of aircraft maintenance record keeping to get a clearer picture of how digitisation is affecting the whole process, and to see what the future holds with regard to the development of the role of artificial intelligence (AI) in record keeping.

Why the digitalisation of aircraft records is becoming increasingly important in the aviation industry

The aviation industry remains one of the most document-intensive sectors, with MROs still relying heavily on paper-based processes for everything from repair orders and work order travellers to certifications, pick tickets, and teardown reports. Despite years of wanting to “go paperless,” the reality is that the majority of MRO workflows are still fragmented by physical paperwork. Most MROs are starting to see the significant impact this has on operations and the difficulties involved in implementing new technologies as a result. Among a number of pain points, Monica Badra, founder of Aero NextGen, comments that: “… the lack of standardisation in MRO processes is a persistent issue, often compounded by undocumented workflows and inconsistent record-keeping. Digitalisation enforces process discipline, drives consistency, and enables benchmarking and continuous improvement—outcomes that are simply not achievable with paper.” She then concludes that: “In summary, digitalising aircraft records is about reducing risk, ensuring compliance, preserving operational knowledge, enabling new technologies, and driving efficiency across the entire MRO value chain.”

Max Lutje Wooldrik, Founder & CEO, AeroDox BV makes the situation clear in terms of financial benefits. “In today’s aviation industry, digitalisation of aircraft records has become critical due to the high financial impact of AOG (Aircraft On Ground) events – costing the industry an estimated US$50 billion annually. When documentation issues delay aircraft return to service, every hour costs between US$20,000-US$140,000. Beyond these immediate costs, digital records mitigate safety risks from counterfeit parts, enhance regulatory compliance, and protect airlines’ reputations. With increasing industry complexity and regulatory scrutiny, paper-based systems simply can’t keep pace with the demands for speed, accuracy, and security that modern aviation operations require,” he advises.

Lucia Soffientini, Airworthiness Manager at Air Worthy also brings up the safety aspect: “Digital records also provide better asset protection as they are securely stored and backed up, protecting critical information from loss, damage, or unforeseen circumstances, such as fire or flooding, thereby safeguarding high-value aircraft assets. By centralising digital records, we can improve communication between MROs, operators, and regulators, which creates better transparency and more effective collaboration. It’s also beneficial for predictive maintenance, helping operators to identify trends, anticipate issues and optimise maintenance schedules, to achieve increased safety and cost efficiencies.” Meanwhile, Daniel Tautges, SVP at Component Control sums up the importance of the digitisation of aircraft records in two short sentences: “The aviation industry is under constant pressure to increase efficiency, reduce downtime, and maintain the highest levels of safety and compliance. Digitalising aircraft records is no longer a luxury—it’s a necessity.”

Sander de Bree, Chief Visionary with EXSYN Aviation Solutions is of a similar opinion to most when he explains that: “The aviation industry is under growing pressure to improve operational efficiency, regulatory compliance, and fleet readiness while reducing costs. Digitalisation of aircraft records is a crucial enabler in meeting these demands. Digital records facilitate real-time data access, reduce administrative burdens, and enable predictive maintenance and better asset value management.” Meanwhile, over at Ramco Systems, Saravanan Rajarajan, AVP & Head of Consulting – Aviation, Aerospace & Defence, is focused on the benefits digitisation brings to operational efficiencies. He informs us that: “The aviation industry consistently seeks avenues to improve operational efficiencies, and digitising aircraft records is proving to be a key driver. Having aircraft records helps in quicker retrieval of technical documents, maintenance logs and history, as well as back-to-birth traceability for troubleshooting. As organisations are adopting digital tools, digitalisation has become the default workflow mode to eliminate paper and reduce errors. The adoption of digital records as a compliance requirement by regulators also increased the momentum.”

The biggest challenges faced in transitioning from paper-based to digital records

The transition from paper to digital records presents several key challenges. Legacy systems integration is often complex, with decades of historical records requiring conversion while maintaining data integrity. There is also significant resistance to change within established processes – aviation is understandably risk-averse, with safety protocols built around paper-based authentication. Max Lutje Wooldrik further points out that: “Regulatory compliance requires demonstrating that digital systems meet or exceed existing security standards. Additionally, standardisation challenges arise across global operations with varying requirements. Finally, the upfront investment in new technology and training can be substantial, though the long-term ROI is clear.” Lucia Soffientini is also acutely aware of the problem created by the volume of existing paper records. “The biggest challenge in moving to digital records is the sheer amount of paper-based data that has to be managed. After the scanning process, records need to be appropriately sub-divided into the so-called “Delivery Bible”, which has to be created in accordance with IATA standards. An aircraft’s technical records are a significant part of its asset value, so the importance of complete and accurate transitioning to digitised records cannot be underestimated,” she says.

Daniel Tautges not only touches on existing paper records but also questions the quality of existing data. “One of the biggest challenges is cultural; teams have relied on paper for decades, and changing habits takes time. There’s also the issue of data quality: converting handwritten or legacy documentation into usable digital formats requires accuracy and robust validation processes. Lastly, there’s the challenge of integration,” he comments. His solution to the problem? “That’s why in Quantum Control, we’ve invested in building an ecosystem where Document Imaging, Maintenance Tracking, and Part History seamlessly interact to reduce manual entry and ensure records are complete, traceable, and compliant.” Sander de Bree highlights many of the frequently mentioned problems when he tells us that “The transition is complex due to fragmented legacy systems, lack of standardization, data quality issues, and resistance to change among operational teams. Additionally, ensuring regulatory acceptance of digital formats poses another significant hurdle.” And his alternative? “EXSYN addresses these challenges by embedding deep domain expertise into every project. Through our aircraft data migration services and our data apps, we provide a structured and proven methodology for digital transformation specifically for airlines that utilise MRO/M&E software systems—ensuring data integrity, process adaptation, and regulatory compliance are maintained throughout the journey.”

“Transitioning to digital records requires significant investment in MRO Systems, integration with customer and supplier systems, end-user training on adoption, change management, regulatory approvals and legacy data conversion,” Saravanan Rajarajan tells us, adding that: “Another challenge the industry has to navigate is varying levels of regulatory acceptance of digital records and varying formats of maintenance documents of older fleets to new fleets.” Meanwhile, Monica Badra focuses on two areas that also deserve equal consideration when it comes to unique challenges faced with such a conversion of paper to digital maintenance records. “Regulatory compliance adds another layer of complexity. Digital records must meet strict aviation authority requirements for authenticity, traceability, and retention. Ensuring that new systems are fully compliant—and that digital signatures, audit trails, and data security measures are robust—requires careful planning and validation,” she highlights, adding that: “Cybersecurity is also a growing concern. As records move online, they become a target for cyberattacks. MROs must invest in robust cybersecurity frameworks to protect sensitive data from breaches, ransomware, and unauthorized access.” She concludes by pointing out that “… cost and resource allocation cannot be overlooked. The upfront investment in technology, process redesign, training, and ongoing system maintenance can be significant—especially for smaller MROs operating on tight margins. We often hear MRO executives say: ‘We could be using these funds to buy more aircraft for teardown or parts to trade; there is a direct and large opportunity cost of investing in digital projects.’ Demonstrating ROI and securing executive buy-in is often a challenge in itself.”

The key technologies driving the digitalisation of aircraft records

Monica Badra also advises us that the digitalisation of aircraft records in the MRO sector is being accelerated by several core technologies that address the industry’s need for accuracy, traceability, and efficiency, which will involve cloud-based document management systems, Optical Character Recognition (OCR) and Intelligent Document Processing (IDP), blockchain, Artificial Intelligence (AI) and Machine Learning (ML), Robotic Process Automation (RPA), e-Signature and digital authentication tools, mobile applications and connected devices, and integration platforms (APIs and Middleware). “These technologies, when strategically implemented, not only digitise records but also lay the groundwork for advanced analytics, improved regulatory compliance, and a more agile MRO operation,” she concludes. Daniel Tautges concurs with Badra in a number of areas as he tells us: “Cloud computing, optical character recognition (OCR), and integration platforms are key drivers. Within Quantum Control, our cloud-hosted ERP enables customers to access aircraft records securely from anywhere. Our eSignature capabilities allow digital sign-offs on maintenance and inspection records. Additionally, we continue to see demand for integrations with barcode and part number scanning—especially when paired with our Mobile Warehouse and Work Order Kiosk modules, which push real-time data from the floor into the digital record.”

Sander de Bree lists cloud platforms for scalable data storage and access, ETL (Extract-Transform-Load) pipelines for data ingestion and standardisation, and again like Badra mentions blockchain for immutable audit trails and APIs and data lakes for integration across systems, as well as AI/ML for data extraction, classification, and anomaly detection. He then informs us that “EXSYN’s NEXUS platform incorporates modern ETL capabilities, integration layers, and automation routines that support fast, scalable, and secure digitalisation initiatives. These technologies allow EXSYN to help operators convert their data assets into strategic advantages.” Meanwhile, Saravanan Rajarajan also highlights the influence of OCR as he explains: “OCR technologies do the heavy lifting in driving digitalisation. They have become more efficient, even converting scanned documents and handwritten notes into structured, searchable digital text. Organisations need to leverage other enabling technologies to get the real value. The data entry point for users should support both structured and unstructured data. For example, while reporting a snag, the mechanics should be able to both type in the data and upload photos, audio, or video files. Replacement of DFP with secure e-sign off augments the digitisation process in compliance with regulatory regimes,” while adding: “The seamless, connected digital ecosystem with suppliers and customers is essential to extending digitalisation benefits and augmenting operational efficiency.”

Also in accord with Badra, Max Lutje Wooldrik highlights blockchain, cloud-based platforms, mobile technologies, APIs and OCR as key technologies. “Blockchain technology stands at the forefront, providing unalterable verification of document authenticity and history. Cloud-based platforms enable secure, global access to documentation. Advanced encryption ensures data security while enabling authorised sharing. Mobile technologies allow for real-time document verification in hangar environments. APIs facilitate seamless integration with existing MRO and ERP systems. And finally, automated document processing with OCR and machine learning reduces manual input while enhancing accuracy,” he tells us. And to back up everyone else, Lucia Soffientini identifies three of the elements most are in agreement with as she explains: “One of the fundamental technologies driving digitalisation is Optical Character Recognition (OCR), which automates the digitisation of paper documents, making historical records searchable and accessible within digital systems. Also, cloud computing enables secure, centralised storage and instant access to records from anywhere, improving efficiency and reducing the risk of lost documentation. We are also seeing the rise of AI and Machine Learning for areas such as analysis and structuring, predictive maintenance and compliance checks.”

How blockchain and cloud-based solutions enhance the security and integrity of digital records

Monica Badra informs us that blockchain and cloud-based solutions are fundamentally reshaping the way MROs manage digital records, especially in terms of security and data integrity. Blockchain technology creates an immutable, time-stamped ledger of every transaction or change made to a record. Once data is entered into a blockchain, it cannot be altered or deleted without leaving a trace. This tamper-evident structure is ideal for maintaining the authenticity and traceability of maintenance events, parts histories, and regulatory certifications. Each stakeholder—MROs, airlines, regulators—can access a single, verified source of truth, which virtually eliminates disputes over record accuracy and supports regulatory compliance. Cloud-based solutions, meanwhile, deliver robust security through advanced encryption, access controls, and continuous monitoring. Data is stored offsite in secure data centres with multiple redundancies, protecting it from physical loss, disasters, or local system failures. Cloud platforms also support granular permission settings, so only authorized personnel can view, edit, or share sensitive records. Regular security updates and compliance certifications (such as ISO 27001 or SOC 2) further strengthen the protection of digital records. She concludes that: “Together, blockchain and cloud-based solutions ensure that digital aircraft records are not only accessible and efficient to manage, but also secure, auditable, and resilient against both internal and external threats. This dual approach is increasingly recognized as best practice for safeguarding the integrity of critical aviation data in a digital-first environment.”

Max Lutje Wooldrik and Sander de Bree also both highlight the security element of blockchain and the creation of an immutable record. Wooldrik goes on to explain that: “At AeroDox, we use multi-level blockchain storage options, including our Level 3 “Ultimate Proof” that utilises multiple blockchains for redundancy even if one blockchain or our platform were to cease operating. Meanwhile, cloud-based solutions provide geographical redundancy, ensuring records remain accessible and protected against physical damage or loss. Together, these technologies establish an unprecedented level of trust in aviation documentation.” In addition, de Bree tells us that “EXSYN leverages secure cloud hosting (e.g., in our platform apps) and has the technical capability to integrate data from MRO/M&E systems to blockchain networks. These architectures are designed to meet the aviation industry’s highest standards for data integrity and regulatory compliance.”

Finally, Daniel Tautges adopts a cautious approach, advising that: “Blockchain has potential for providing a tamper-proof ledger of maintenance activity, but most MROs and operators are still in the early stages of adoption. Cloud-based ERP systems, however, are already providing high levels of security and audit traceability. With Quantum Control’s cloud infrastructure, powered by Amazon Web Services, customers benefit from encryption, role-based access, and automatic backups—ensuring that aircraft records are both protected and permanently accessible, even during audits or lease transitions.”

The roles artificial intelligence (AI) and machine learning play in managing and analysing digital aircraft records

Artificial intelligence (AI) and machine learning (ML) are transforming how digital aircraft records are managed and analysed in the MRO sector. Their role extends beyond simple automation—they are enhancing accuracy, efficiency, and strategic decision-making across maintenance operations. AI and ML algorithms can automatically extract, classify, and validate data from a wide variety of digital records, including maintenance logs, inspection reports, and compliance documents. This minimises manual data entry, reduces errors, and ensures that records are consistently organised and easily searchable. Predictive maintenance is one of the most impactful applications. By analysing historical maintenance records, real-time sensor data, and operational trends, AI/ML models can predict component failures or maintenance needs before they occur. According to recent industry research, predictive analytics can reduce unscheduled aircraft maintenance by up to 30% and lower maintenance costs by up to 22%. This not only minimises downtime and extends component life but also optimises inventory management and resource allocation.

Monica Badra at Aero NextGen goes on to tell us that: “AI-driven analytics also support regulatory compliance and quality assurance. Machine learning models can flag anomalies, identify patterns of non-compliance, and ensure that records meet evolving regulatory standards. This proactive approach helps avoid costly audits and penalties. Moreover, AI bridges communication gaps between departments by providing a unified view of maintenance needs, improving collaboration and coordination. AI-powered dashboards and reporting tools deliver actionable insights to both technical and management teams, enabling faster, data-driven decisions. In summary, AI and machine learning are critical enablers for maximizing the value of digital aircraft records. They drive efficiency, reduce operational costs, enhance safety, and support continuous improvement in MRO operations.”

Over at Component Control, Daniel Tautges points out that AI and machine learning are transforming how we interact with large volumes of historical data. Predictive analytics, for instance, can flag recurring component failures or maintenance trends. He then goes on to advise that: “In Quantum Control, we are actively enhancing our Resource Planning, Work Order and Customer Service modules with AI-assisted tools to surface insights from historical work orders, inspections, and parts usage. These insights empower MROs and operators to make proactive, rather than reactive, decisions.” Interestingly, Max Lutje Wooldrik at AeroDox makes mention of how AI can look into our past to help improve our future, telling us that: “AI and machine learning are revolutionising how we interact with aviation documentation. These technologies enable automated validation of documentation completeness, flagging missing or expired certificates. Pattern recognition identifies potential compliance issues before they become regulatory problems. Advanced search capabilities locate specific information across thousands of documents in seconds. Predictive maintenance becomes possible by analysing maintenance records alongside operational data. And perhaps most valuably, AI can extract actionable insights from historical records to improve future maintenance planning and inventory management.” Likewise, Sander de Bree also points to predictive analytics as he explains: “AI/ML techniques streamline the processing of unstructured maintenance documents, automate anomaly detection, and enable predictive analytics. This supports better decision-making and reduces the risk of compliance violations. EXSYN applies AI/ML within AVILYTICS, allowing operators to move from reactive to predictive maintenance strategies. Our systems ingest aircraft data and apply analytics to identify reliability trends, potential component failures, and optimisation opportunities—driving value directly from digitalised information.”

To close, Saravanan Rajarajan at Ramco Systems looks to the benefits that OCR brings with it. “The MRO maintenance process typically generates a wealth of data pertaining to defects, parts consumed, labour hours, elapsed time, etc. Accumulated over time, this data can be converted into a competitive advantage by leveraging AI/ML tools. OCR powers the extraction of data from legacy paper documents and AI/ML tools utilise this data to perform classification, anomaly detection, or provide suggestions. For example, when a mechanic reports a defect, the system leverages the historical records pertaining to the type of aircraft and ATA code to suggest a list of similar defects that were resolved in the past. Based on the mechanic’s decision, the system prompts the resolution options, reference manuals, and parts and tools required to fix the defect.ssssssssssssssssss However, the final determination of accepting the recommendations still lies with the mechanics.AI/ML-based chat assistants allow users to interact with the backend aircraft record through plain text inputs and generate insights for decision-making,” he advises.

How airlines and MROs can ensure seamless integration between different digital record-keeping systems

Ensuring seamless integration between different digital record-keeping systems is a major challenge for airlines and MROs, given the diversity of legacy platforms, ERPs, and specialised maintenance solutions in use across the industry. According to Daniel Tautges, “The key is to adopt platforms that are open, modular, and API-driven. Quantum Control offers robust integration capabilities through our suite of APIs that allow customers to connect seamlessly with e-signature tools, OEM portals, lessor platforms, and regulatory marketplace systems. Whether it’s syncing logbook entries with maintenance forecasts or updating records across partner systems, integration is about enabling a single source of truth—accessible across the organization,” he tells us. Max Lutje Wooldrik is a proponent of a multi-faceted approach as he explains: “Successful integration requires a multi-faceted approach. First, adopting industry-standard APIs and data formats creates inter-operability between systems. Open architecture platforms like AeroDox can function as middleware between legacy systems and newer technologies. Phased implementation approaches minimise operational disruption while allowing for incremental improvements. Collaborative industry initiatives like Blockchain for Aviation (BC4A) help develop shared standards. And finally, selecting solutions with strong integration capabilities from the start prevents creating new data silos.”

Both Saravanan Rajarajan and Sander de Bree provide succinct responses. “Airlines, MROs, and OEMs use different software platforms and data exchange policies. Adopting industry standards like Spec 2000 or data models like S1000D will ease the onboarding process and reduce system-specific changes. Data exchanges between the organizations must be enabled through an API to ensure security and interoperability,” says Rajarajan, while de Bree concurs, adding that “Seamless integration requires interoperability frameworks (e.g., S1000D, ATA Spec standards), open APIs, robust data governance models, and a centralised data operations layer.”

Monica Badra goes into considerable detail as she advises that several proven strategies and best practices can significantly improve integration outcomes, including adopting industry standards and data formats, leveraging APIs and Middleware, prioritising interoperability during vendor selection, implementing Master Data Management (MDM), continuous testing and validation, early involvement of stakeholders, and planning for scalability and future growth. “By following these best practices, airlines and MROs can achieve seamless, efficient, and reliable integration between digital record-keeping systems—ensuring that critical data flows smoothly across operations, supports compliance, and enables advanced analytics,” she says.

What the next expected major developments in aircraft record digitalisation will be

Here the recurring theme among respondents would appear to be digital twins and an increased use of AI. “We’re heading towards fully integrated digital twins where physical aircraft have comprehensive digital counterparts including complete documentation history,” says Max Lutje Wooldrik. “Advanced analytics will increasingly provide predictive insights from historical records to optimise operations. Mobile verification technologies will become standard for field technicians. Industry-wide blockchain networks will enable seamless verification across the supply chain. And regulatory authorities are increasingly accepting fully digital documentation methods, accelerating adoption industry-wide,” he adds. Beyond this, Saravanan Rajarajan makes it very clear that “There is a need for collaboration and alignment between industry bodies, lessors, aircraft manufacturers (OEMs), airlines, MROs, and regulators to set interoperability standards, data structures, formats, and protocols, and enforce compliance,” adding that: “Currently, there are challenges with siloed blockchain networks, which limit the potential. Another limiting factor is whether the chain includes all the supply chain players, including the MROs, tier-2 & -3 suppliers, etc. Arriving at the standards and alignment will bring in data integrity, making it nearly impossible to falsify maintenance or certification history.”

Sander de Bree anticipates regulatory standardisation for e-signatures and digital logbooks, end-to-end digital aircraft lifecycle records (from OEM to phase-out), increased use of AI for automated airworthiness assessments, digital twins and real-time record syncing from sensor data, while pointing out that “EXSYN is actively contributing to this future by helping shape digital MRO ecosystems and embedding data integrity, traceability, and automation into every aspect of aircraft configuration and airworthiness management.” Beyond this, as well as AI, Daniel Tautges talks about ‘mobile-first tools. “We expect more AI-powered automation, real-time collaboration with OEMs, and tighter integration with third-party systems. Another major development is the use of mobile-first tools—mechanics on the shop floor want to update digital records instantly, not at the end of their shift. That’s why we continue investing in our Mobile Maintenance and Digital Task Card functionality within Quantum Control, reducing the friction between performing work and documenting it,” he comments.

According to Monica Badra, one key development is the adoption of end-to-end digital workflows powered by AI, IoT, and cloud-native platforms. MROs can easily find their match after completing a short survey. These systems will enable real-time data capture directly from the shop floor, integrating inputs from technicians, sensors, and connected tools into a unified digital record. This will reduce manual data entry, minimise errors, and provide instant access to up-to-date maintenance histories. She then explains that another major development is the increased use of blockchain for secure, tamper-evident record-keeping and regulatory compliance. As more aviation authorities and OEMs recognise blockchain’s potential, we can expect broader industry adoption for tracking parts provenance, maintenance events, and airworthiness certifications—creating a single source of truth accessible to all stakeholders. She then expands further. “Interoperability is also advancing, with the emergence of open data standards and low-code integration platforms. These tools will allow airlines, MROs, lessors, and regulators to seamlessly exchange digital records across different systems, eliminating silos and manual reconciliation. This is especially important as M&A activity and global fleet growth increase the complexity of record management. Augmented Reality (AR) and Mixed Reality (MR) are set to play a bigger role in both record-keeping and technician training. By overlaying digital records and instructions onto physical assets, AR/MR will streamline maintenance processes, reduce errors, and accelerate onboarding for new staff. Finally, predictive analytics and advanced reporting will become standard, leveraging the vast amounts of structured digital data now available. These tools will support proactive maintenance planning, regulatory audits, and business intelligence, driving higher efficiency and compliance. In summary, the next phase of digitalisation will be characterised by intelligent automation, secure and interoperable data exchange, immersive technologies, and data-driven decision-making—transforming aircraft record management into a strategic asset for MROs and airlines.”

Could digitalisation eventually eliminate the need for physical aircraft records?

Ever since the digitisation of aircraft records began, this has been the question on most people’s lips. However, the answer is not that simple, primarily because of the overarching nature and reason for aircraft maintenance documentation – regulatory compliance and rigorous safety measures. Add to that a reluctance for change and total industry adoption and then there is a possibility all aircraft records could become digital. As Monica Badra tells us: “In many regions, digital records are already recognised as legally equivalent to paper originals, provided they meet strict requirements for authenticity, traceability, and security. Cloud-based platforms, blockchain, and advanced digital authentication tools now make it possible to create, store, and manage aircraft records entirely in digital form—accessible instantly and protected against loss or tampering. However, the complete elimination of physical records is still challenged by inconsistent global regulations, legacy processes, and the need for interoperability across diverse stakeholders. Some authorities and lessors still require or prefer hard copies for certain transactions or audits, and many organisations maintain physical backups as a risk-mitigation strategy. That said, the direction of travel is clear: as regulators, OEMs, airlines, and MROs gain confidence in the reliability and security of digital solutions, the industry will steadily move toward fully paperless record-keeping.”

“The aviation industry is undoubtedly moving toward a fully digital future, but the transition will be gradual,” says Max Lutje Wooldrik. “Digital records offer superior security, accessibility, and efficiency compared to physical documentation. Regulators are increasingly accepting digital verification with proper controls in place. The COVID-19 pandemic accelerated digital adoption by forcing remote work and reducing physical document handling. In AeroDox’ view, physical records will become increasingly rare and eventually obsolete, but the transition must be managed carefully to maintain the industry’s exceptional safety record,” he concludes.

Lucia Soffientini at Air Worthy concurs with Monica Badra and what is already accepted in terms of digital records. “Yes, this is already happening. Aviation regulatory authorities already allow record keeping either with hard copies or EDP (Electronic Data Processing) versions. Some operators are also using electronic Aircraft Technical Logs to avoid paper on sustainability grounds and there are some Maintenance Tracking Systems in the industry that are completely paperless. Regulatory acceptance is advancing, with many authorities now supporting electronic records, and industry surveys show most operators face few regulatory barriers to digital adoption. Technologies like AI and blockchain are making digital records even safer and more reliable. Whilst there is some resistance, mainly due to concerns about data security, the switchover to digital records is becoming the norm and the need for physical records is diminishing. We expect that the advance of digitalisation will eventually eliminate the need for physical aircraft records, but the timetable is not fixed on this,” she advises.

Daniel Tautges, Sander de Bree and Saravanan Rajarajan are also all in agreement that it is pretty much a question of ‘when’, not ‘if’, in terms of aircraft maintenance records becoming fully digital as the norm. “Although some operators may continue to use hybrid systems in the near term—due to legacy infrastructure or regulatory constraints—the long-term direction is clearly toward fully paperless airworthiness environments,” says de Bree. “Though the timeline is uncertain, digitalisation will eventually eliminate the need for physical aircraft records. This change will arise due to several factors, such as operational efficiency needs, regulatory compliance requirements, momentum, technological advances and environmental needs. The rate of change may vary depending upon the regulatory regimes and organizations’ trust in technology,” explains Saravanan Rajarajan. “Regulators in multiple regions now accept digital records as the source of truth, provided they meet traceability and integrity standards. With Quantum Control’s Document Imaging and Certification Tracking, physical binders are quickly becoming obsolete. That said, complete industry-wide transition requires continued alignment between software providers, OEMs, lessors, and regulatory bodies—but we’re well on our way,” concludes Tautges.