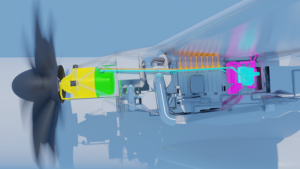

Collins Aerospace, a business unit of RTX, marked a momentous occasion on July 20, as it unveiled the inauguration of a US$14 million (£10.9 million) expansion for its additive manufacturing centre in West Des Moines, Iowa. Spanning 9,000 ft², the expansion provides ample space for housing multiple state-of-the-art 3-D metal printers. Notably, the first printer installed boasts a build volume eight-times larger than the facility's existing printers, significantly enhancing the centre's additive manufacturing capabilities.

Renee Begley, the West Des Moines site lead for Collins Aerospace, emphasised the pivotal role of additive manufacturing in the future of the aerospace and defence industry. From supporting commercial aircraft backlog to enabling future platforms and reducing carbon emissions, additive manufacturing presents numerous opportunities for innovation. The expansion stands as an investment in the business, poised to deliver substantial benefits to customers, such as reduced weight, complexity, lead time and cost in supplied parts.

The Collins Aerospace West Des Moines facility stands at the forefront of engine component design and production for both commercial and military aircraft. The addition of these new printers opens avenues for exploring additive production of these components, complementing the facility's current production of land-based turbine components. Moreover, the West Des Moines site proudly joins an elite group of only eight facilities in the U.S. to receive the prestigious National Aerospace and Defence Contractors Accreditation Programme (NADCAP) certification for additive manufacturing.

With a strong commitment to additive manufacturing, Collins Aerospace maintains a global network of additive production centres in Iowa, Minnesota, North Carolina, and Singapore. Additionally, the business operates an additive research centre in Connecticut, further solidifying its dedication to advancing this critical focus area within the aerospace industry.