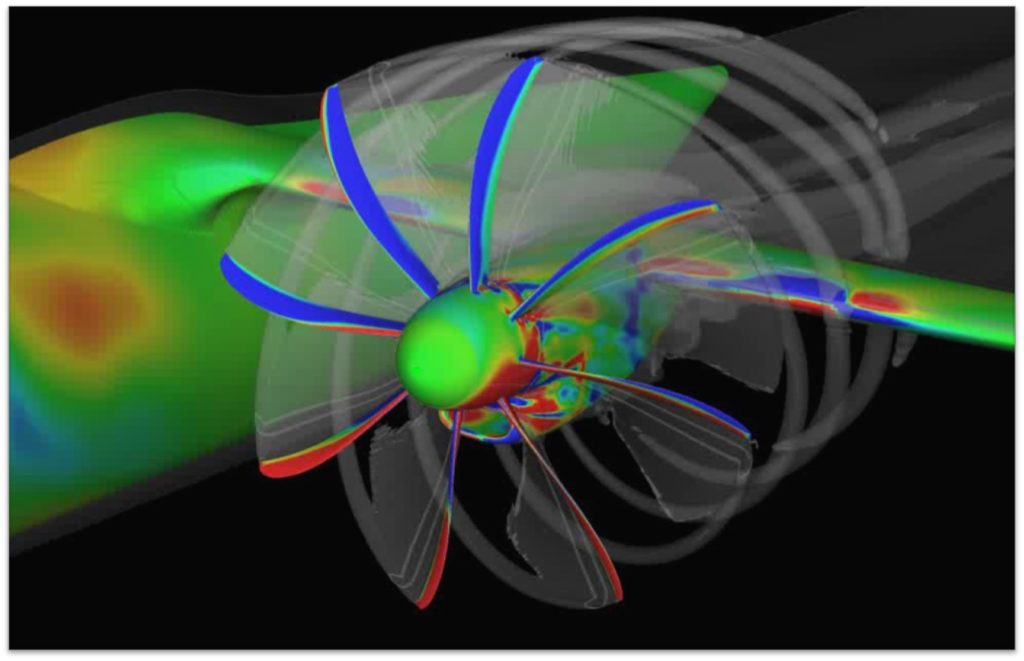

Dowty Propellers, a global leader in composite propeller systems, has announced the successful completion of its largest-ever propeller R&D program.

Dowty led the four-year Digital Propulsion (DigiProp) research and development program in collaboration with three of seven of the U.K.'s High Value Manufacturing Catapult centers. This was an ambitious £20 million (US$27.6 million) project, part funded by the U.K. government, that sought to innovate every aspect of the design, manufacture, and testing of its propeller systems.

Dowty Propellers collaborated with three U.K. innovation centers on the DigiProp project. The National Composites Centre (NCC), The Manufacturing Technology Centre (MTC) and The University of Sheffield's Advanced Manufacturing Research Centre (AMRC); all members of the High Value Manufacturing Catapult. The partners offered subject matter expertise on both established and emerging technologies, allowing Dowty Propellers to unlock some of the best next-generation capabilities and innovations that the U.K. has to offer.

“This project has delivered innovations in propulsion performance and cost through design and productivity which has helped to transform R&D for propellers,” said Mark Scully, Head of Technology for Advanced Systems & Propulsion at the Aerospace Technology Institute. “With the assistance of the High Value Manufacturing Catapult partners, the manufacturing innovation has been deployed into the new state-of-the-art Dowty facility in Gloucester. This provides an excellent foundation for Dowty and the U.K. to secure future sustainable aerospace opportunities.”

Dowty Propellers is now beginning to use the next-generation technologies realized in DigiProp for evolving aircraft applications and to target next-generation platforms. Potential customers are benefiting from its ability to support customer attribute trade studies with short turnaround time on performance analysis.